| |

NON-CLOG SUBMERSIBLE SEWAGE

PUMPS:

|

| |

Non-clog

submersible sewage pumps offer simple, the most economical

and most reliable way of solving the pumping and disposal

of sewage containing suspended solids “Powerpoint”s

rich experience over several years in the field of designing

and manufacturing of varieties of pump sets has built up

technical know-how and expertise in designing of reliable

and efficient pumps. which need practically on maintenance. These compactly designed pumps are easy to handle and can be installed permanently with the help of automatic

couplings in a small sump from where sewage is to be pumped

or can be used for portable duty. Being submersible they

do not require and pump house. |

|

|

| 7 |

Profile Gasket:

|

| |

Ensures flexible, pressure-light

and automatic connectionbetween pump and duckfoot band. |

| |

|

| 8. |

Double Mechanical Seals:

|

| |

All pumps have

as standard equipment double mechanical seals which seal off

the motor from the pump section. The seal has faces made from

silicon carbide for long life. The design of the oil chamber

ensures efficient cooling of the seals. |

|

| |

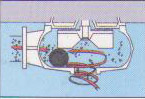

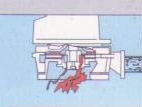

CONSTRUCTION: |

| |

"Powerpoint” non-clog submersible

sewage plump are of close

coupled compact design and having a pump below and a motor

above,

sump cleaning is possible to a maximum level. These are power

ed by squirrel cage induction dry motors suitable for operation

at 400/400 volts, 3 phase. 50 Hz, Ac supply. Being submersible, they save a lot of costs on construction compared to other

conventional pumps. They also are noice free in operation.

|

| 1. |

Bearings:

|

| |

The bearing arrangements

with double angular contact ball

bearings with deep grove ball bearings give the best resistance

pump. The life rating is over 40000 hrs. The bearing are lubricated

for life with a high temperature grease.

|

| 2. |

Dry, Squirrel cage 3 phase motor:

|

| |

The housing is totally dust

& waterproof for submersible duty.

The cooling is done externally and the special insulation of

the winding takes care of rises in temperature during intermittent

operation. |

| 3. |

Cable Joint:

|

| |

Special triple protection does not permit

any liquid entry into the dry motor

|

| 4. |

Moisture detection probe:

|

| |

The moisture detector

indicates any moisture penetration into the motor.

|

| 5. |

Thermal Motor Protection:

|

| |

Built-in temperature sensors enable tripping of the motor if

the temperature rises above 150 deg.C.and restarts at 80 deg.C,giving

complete dry run protection. Maximum permissible liquid temperature

is 50 deg.C.

|

| 6. |

Guide Device with single/double

guide rail:

|

| |

The guide rail systemfor lowering

and lifting the pump is an outstanding feature. The pump slides

down on to the duckfoot bend and engages with it without bolting. It

is not necessary to enter the sump to carry out inspection

and maintenance work.

|

|

|

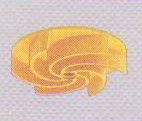

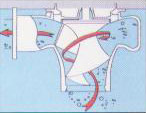

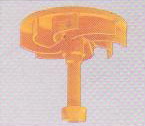

| 9. |

Energy saving

impellers to suit different applications: |

| |

Depending on the liquid ,impellers

may be semi-open

or closed, running against a wear disc or casing ring.

For industrial sewage, single channel, two channel or

vortex impellers, can be used. |

| |

|

| 10 |

Shaft with rotor:

|

| |

A shaft with a die-cast rotor

on the motor side and a shaft protection sleeve on the pump

side,ensures better life for the shaft. The compact seal arrangement

has minimised shaft over -hang and consequently minimises shaft

deflection. |

| 11 |

The motor portion

is isolated from the pump by an inter mediate casing with double

mechanical seal in the oil chamber. |

|

|

|

|

|

VORTEX

IMPELLER

Vortex impellers are selected for applications

having long, stringly solids in the pumped liquid or for pumping

solids with high solids concentration |

|

A vortex impeller creates a wirlpool

or vortex inside the pump volute, solids pass through this vortex

rather then through the impeller. |

| 2

.

|

ROBOTEX

IMPELLER

The special clog-free design of the spiral

vanes impeller makes this pump the first choise for applications

where the key words high efficiency, high suction lifts ,minimum

product damage and low flow disturbance. Mainly used for heavy

& activated sludge. |

|

|

|

|

|

GUIDE

BAR COUPLING:

Guide bar type quick release coupling for

stationery

wet installation .The pump is automatically coupled to

the bend.

IMMERSIBLE:

For stationery installation in a dry sump.Motor

in a flood-proof design with efficient cooling system. Both

for horizontal and vartical installations.

TRANSPORTABLE:

Pump with support and hose adapter for

temporary wet installation. The pump can easily

be moved to other sites . |

|

|

3.GRINDER

PUMP

For limited quantities of water that

require small discharge pipes. Solids are cut into vary small

particles that can be pumped through these small pipes without

risk of blocking.

|

|

|

| 4. |

AGITATOR

FOR HIGHEST DENSITY

The agitator which is mounted just below the

intake opening feeds the impeller with high density material. This in combination with the strong vortex created by the

impeller ,leads to unmatched solids concentration. Strong

surface boundaries are mechanically broken, making solids below

accessible for pumping. Oversizes solids are thrown away from

the intake, preventing accumulation of large solids that

would impair performance. |

|

|

|

|

| MUNICIPAL SECTOR: |

| .Pumping Station |

.Airports |

| .Hotels |

.Liftinh Station |

| .Subways |

.Sewage Works (treatment

plant) |

| |

|

| INDUSTRY: |

|

| .Iron & Steel |

.coal and Oil-fired Stations |

| .Cellulose |

.Food Processing Industry |

| .Paper |

.Sea Water |

| .Mechanical Engineenng |

.Industrial Water |

| .Chemical Industries |

.Refinery |

| .Sugar |

. |

| |

Capacity

|

:Upto 2500 m3/hr

|

Head

|

:upto 65 mts.

|

Solid size

|

:upto 150 mm

|

H.P.

|

:2 to 250 HP

|

| RPM |

:960/1450/2900 |

|

|

5. OPEN SINGLE CHANNEL

IMPELLER

In order to achieve the best possible

solids handling performance, the single channel impeller pumps

are equipped with an open single channel impeller running

against an adjustable suction cover. |

|

6. DOUBLE CHANNEL

IMPELLER

For achieving the highest possible efficiency

the larger channel pumps are fitted with a double shrouded

channel impeller with rubber wear rings.

|

Back to Home Page

|

|

|

| |

No pump house required

|

civil cost saving 50%

|

can be installed in a collection well

|

It can pump out water from the bottom

lavel

|

| Being portable it can be shifted / handled

easilly |

|